Open Source Drum Pedal project

Files are available through this GitHub repository.

Files are available through this GitHub repository.

Discuss on this Discord Channel to share ideas and progress about these projects.

Discuss on this Discord Channel to share ideas and progress about these projects.

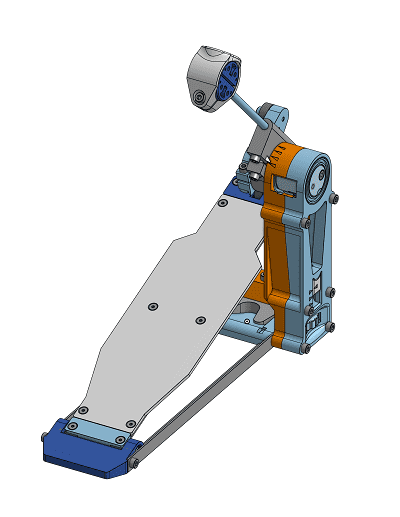

Open Source Drum Pedal V2

Similar to the V1, this version doesn't have much documentation. It's mostly an iteration with a few improvements.

Concept

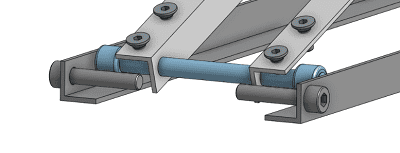

Considering 3/8" square aluminum are rare and most suppliers don't supply them, I decided to witch to 1/2" 90° angle. For this version, the thickness is 1/16".

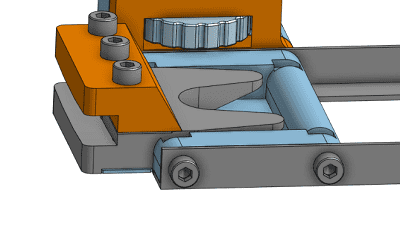

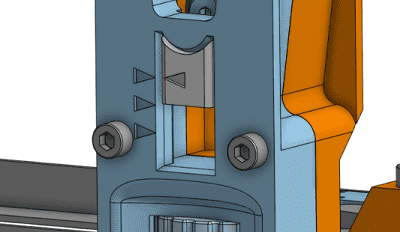

This is my first iteration for a simple hoop clamp. As you probably know, the hoop clamp exert a pinching force on the hoop to keep the pedal in place. This pinching force needs to be quite high, as most clamp will slide over time. Using 3D printed parts, I knew it would take something very massive in order to clamp it tight.

I decided to opt for something similar to the Sonor Giant Step, which they call "Smart Connect". The goal is to clamp a 3D printed part on the hoop, and slide the pedal under the small hooks. There is no clamp system like on the Sonar's system, this one rely on the bass drum weight to stay in place.

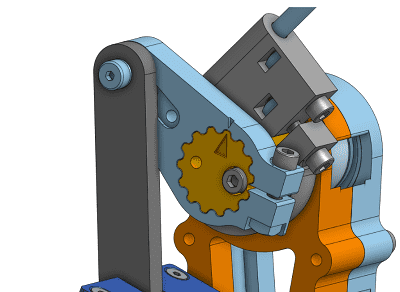

A simple grooved shaft allow a position / angle change for the board. I personally prefer this feature over the un-grooved design for the beater. Having a precise set for each position allow the user to easily change a setting and replicate it over more pedals.

Markers are added where adjustment can be made. This will help adjust two pedals to the same settings.

New challenges

- Board reinforcement are too weak and can bend over weight

- Vertical frame bends with the feet weight

Unresolved

- There is a still lot of plastic needed, and the printing time is quite high.

- Poor clearance for the feet.

- Poor lateral stability.

Resolved

The tension knob is hard to access and difficult to rotate.The 3/8" square extrusion tubes are very uncommon and are a poor choice in terms of cost.No hoop clamp.