Open Source Drum Pedal project

Files are available through this GitHub repository.

Discuss on this Discord Channel to share ideas and progress about these projects.

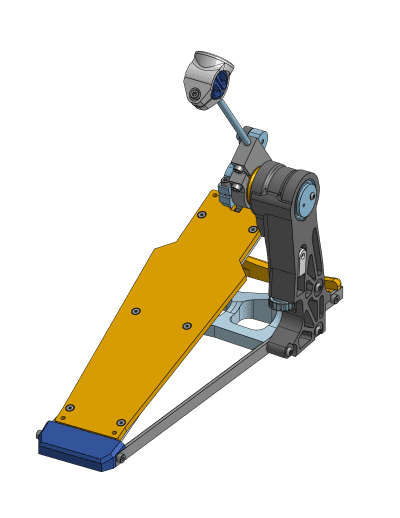

Open Source Drum Pedal V4

At this time of writing, the V4 is still the version I'm using on my drum. The V5 was a test for a different design (should have called it a forked version), and the V6 is still in construction.

I'm still impressed by the fact that no parts have broken. I've designed them as I thought it would be enough, but I was pretty sure one of two would be damaged over time.

This version has quite a few less modifications from the V3 than the V3 had from the V2. I wanted to make some minor fixes and see how an improved version behaves. From that point, I'll need to decide if I keep going in this direction, or if I make major changes.

Concept details

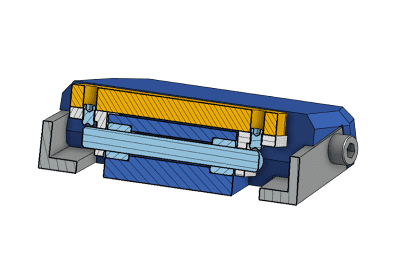

Heel block bushings

I decided to insert the bushing into the heel block rather than outside it. This isn't a major change, but I found that it is now much cleaner and feels stronger too. I didn't like the design from the previous version where both the bushings and the frame were attaching to small 3D printed legs. With this modification, I managed to space the 90° angles further away from each other, improving the board stability a little.

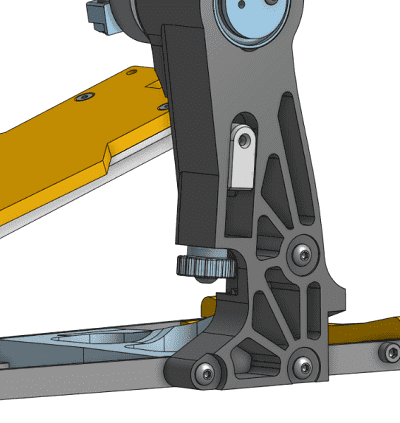

Vertical housing improvements

The vertical housing was probably the main weakness from the last design, where it would bend on each foot press. At the same time, this part is taking quite a lot of plastic, and by the same way, printing time. If I'm removing too much plastic, the part will bend even more, and if I add too much, the printing time will increase further.

First, I had to move the knob to the front, as it was too hard to access. Then, I made a rib design to reduce the amount of polymer while trying to keep the part strong in a direction.

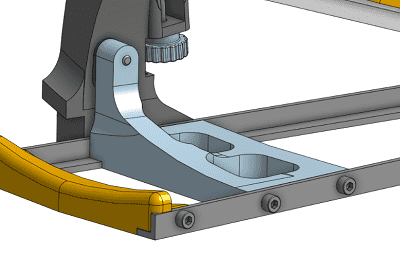

Reinforcement

I also added a part that would connect both 90° angles and also support the vertical housing. This is very close to the best I can do, as getting higher with the support will lead to an interference with the pedal moving.

Simplified spring bushing

In the previous versions, I used to print a small sleeve with a groove to keep the spring in place. After doing some tests with bronze bushings, it turns out it's perfect for our application. I switched from needle bearing to bronze bushing, which allowed me to embed a small groove in them to hold the spring in place.

1/4" birch plywood foot pedal

Even though I did the V3 with this material, the CAD was still based on the 1/8" acrylic. I was very satisfied with the look and feel from the wood. It's a very durable solution, and I'll probably keep using it from now on.

New challenges

- A design review is required, as there are many unresolved issues. We need to go back to the drawing board!

Unresolved

- There is a still lot of plastic needed, and the printing time is quite high.

- Vertical frame still bends with the feet weight

- Assembly with the single part housing is challenging, and requires a lot of manual fixing after the printing

Resolved

1/8" Acrylic feels weak for the boardSpring tension is hard to adjust from the back of the vertical housing