Open Source Drum Pedal project

Files are available through this GitHub repository.

Discuss on this Discord Channel to share ideas and progress about these projects.

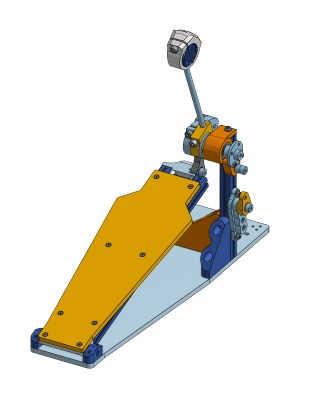

Open Source Drum Pedal V6

The V5 was an interesting iteration, but the drawback were too bad to keep going that way. I wanted to go with something very traditional and see how it played. The challenge with 3D printed parts is the stress involved in clamping. I've seen quite a lot of components crack after a while, which is definitely something I wanted to avoid.

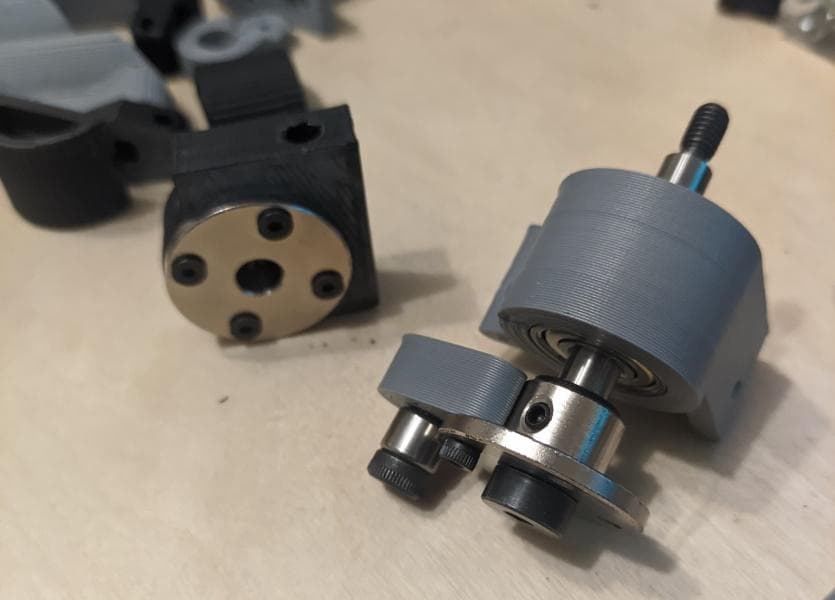

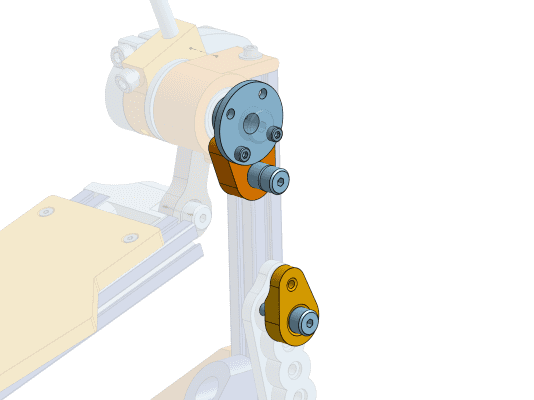

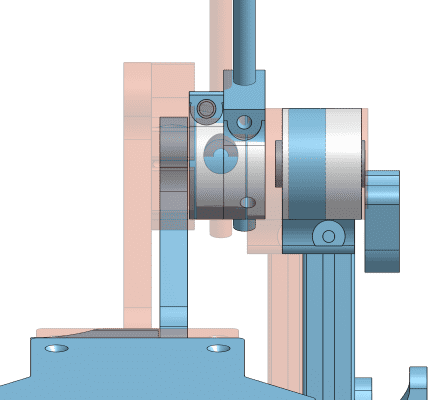

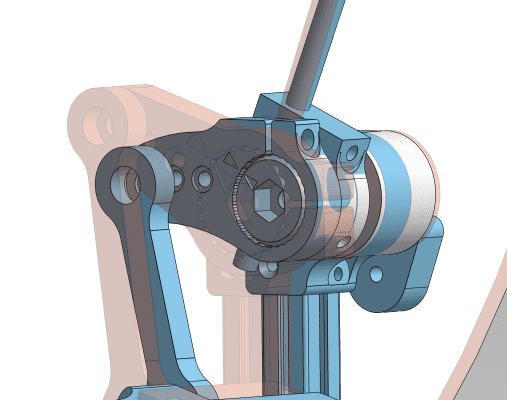

The 8 mm bearing and shoulder screw combination was quite pleasant to work with. However, there is no space in the current design to fit the spring on the same side as the beater and the board link; the main bearing would be too far. As I want to keep it adjustable and easy to print, it would quite a challenge to realize something like the DW 9000 has done:

I found something called a flange shaft coupling, which would be perfect to transmit the torque from one side of the pedal (beater and link) up to the other side (spring). The metal frame and fabrication would make it easy to tighten the screws and make sure it's not slipping or breaking.

Concept details

Switched to a tension spring

The compression spring was an interesting concept, but it's time to back to something more adjustable. Right now, I've made something that is very simple, where 4 settings are available by changing the screw position. If I'm satisfied with the design, I'll check for a more pleasant way do adjust the spring tension.

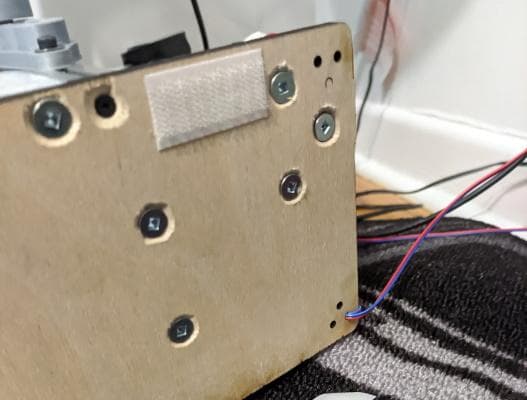

Thread in plastic rather than thread in wood

I wanted to fix the 3D printed components from the bottom, while using special threaded screws designed for plastic parts. As it turns out, I couldn't get the right screw for anti-dumping reasons (again), so I had to use wood screw. By running some tests, I managed to find the right pre-drilling hole size to make sure the parts weren't cracking. However, I didn't enjoy this process as this hole size can be different for each type of polymer used.

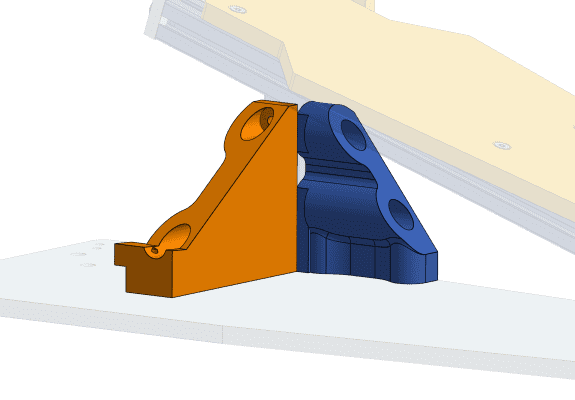

Stronger vertical frame brackets

I just thought the bracket design for the V5 were a bit too simplistic and looked weak. This was a good thing was the tapping screw in the plastic would have broken the previous design, this one didn't crack at all.

More space for the foot

I wanted to stop trying to place the link in the center of the board and move it closer to the vertical frame. This will shift everything on the right, and let more space for the foot. Also, I moved the screw adjustment on top, leaving more clearance once more. These are minor tweaks, but I've been getting my toes hit sometimes by the screw on the V5, which is annoying. The previous setting can be seen in red.

Lowered the link default angle

I realized after that it was a bad idea, but I moved it horizontally. This lead to a very poor feel and attack, I had to adjust it back to the same angle as before, but then the board angle was quite high. The previous setting can be seen in red.

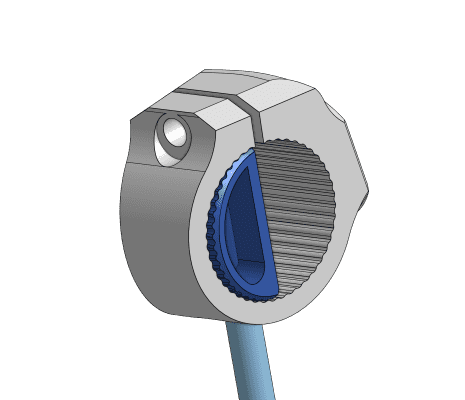

Beater clamping slot is now vertical

It actually took me 6 versions to realize that putting the slot vertical will greatly improve the beater grip... Otherwise, it could fall quite easily from the shaft.

Complete list of changes

| From Version | Description | Done | Stage | Notes |

|---|---|---|---|---|

| V6 | Rotate beater screw to apply pressure on the shaft | 2021-07-18 | ||

| V6 | Rotate arm screw to clear space for feet | 2021-07-18 | ||

| V6 | Use a single extrusion for the board in diagonal | To evaluate | Lots of modifications needed | |

| V6 | Reduce the beater shaft length | 2021-07-18 | ||

| V6 | Make beater a little thicker | 2021-07-18 | ||

| V6 | Move the link away from the feet zone | 2021-07-21 | ||

| V6 | Make pedal wider | 2021-07-18 | ||

| V6 | Add threaded insert for shoulder screws | Obsolete | Shoulder were loose on the previous version (Spring against the board), causing a weird play between the beater and the board | |

| V6 | Bring rotation closer to the bass drum head | 2021-07-21 | ||

| V6 | Revert to tension spring | 2021-07-31 | ||

| V6 | Switch to self tapping in plastic | 2021-07-31 | ||

| V6 | Add Spacers to prevent bearing damage | 2021-07-25 | ||

| V6 | Reduce the maximum setting for the arm length | 2021-07-21 | Removed 5mm | |

| V6 | Switch the spring on the right side | 2021-07-21 | ||

| V6 | Use shaft flanges to couple the torque to the shoulder screw | 2021-07-21 | ||

| V6 | Quick remove / adjust spring | Cancelled | Didn't look good / reliable | |

| V6 | Roller Spring Adjust | 2021-07-31 | ||

| V6 | Adjust link hole angle to prevent board from changing height | 2021-07-31 | ||

| V6 | Separate the Spring adjust from the Feet Strenghtener | 2021-07-31 | ||

| V6 | Improve Strengthener Width design | 2021-07-31 | ||

| V6 | Added vertical extrusion threaded hole | 2021-07-31 | ||

| V6 | Switch screw side from Pedal Link | 2021-08-01 | ||

| V6.1 | Fix bearing clearance | 2021-08-22 | ||

| V6.1 | Add beater shaft stopper at beater | 2021-08-22 | ||

| V6.1 | Clearance for SHCS for the beater holder | Cancelled | This side needs to be fixed with the shaft (Shoulder screw), due to the hex nut attached to it. The spring will be adjusting the board angle. | |

| V6.1 | Move flat head down to clear the nut on the bearing holder | 2021-08-22 | ||

| V6.1 | Remove the interferrence hole in the beater holder | 2021-08-22 | Adding this screw prevent installation of the beater shaft | |

| V6.1 | C.Sunk are too close to the board edges for flat head | 2021-08-22 | These parts were made thicker, and should be printed in a different orientation | |

| V6.1 | Improve Link Base assembly for 2 internal screws | 2021-08-22 | Shortened the board, added chamfer on the link base | |

| V6.1 | Strenghten heel bearing holder for screw | 2021-08-22 | Added 2mm. Change in printing direction will greatly help | |

| V6.1 | Scale Down the beater inside parts in the length axis | 2021-08-22 | For some reasons, only the edges (top and bottom) are touching. Removed 0.50mm in height (non-uniform scale) |

Conclusion

I've played with both the V5 and V6 for a few months now, and I'm pleased with the improvements the V6 has brought.

However, I feel like the two steel flange coupling added quite a lot of weight to the system, the pedal feels a bit heavier and harder to control. I'd like to try something different with the next version, something lighter.

Also, some parts have cracked during adjustments. For this reason, the next version will have heat-set insert for important adjustments.