Open Source Drum Pedal project

Files are available through this GitHub repository.

Discuss on this Discord Channel to share ideas and progress about these projects.

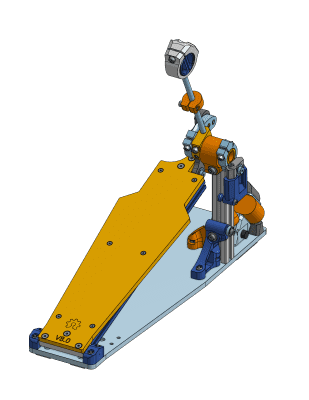

Open Source Drum Pedal V8

The V8 took me over 2 months to design, probably one of the longest update so far in this project. This version required much more fine-tuning than the others. I had to fix a couple of issues which lead to 4 smaller versions (V8.4) after the initial release.

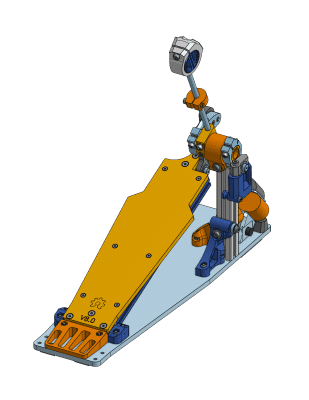

The two major features in this version are the belt drive and the short board. I've been working on a longboard & direct drive version since the beginning, but I wanted to make this project more versatile. There is currently only one shape available for the belt drive, but the mounting is done with only 3 screws and adding new options like the Pearl Eliminator would be very easy.

Most of the other changes improves the assembly and fabrication. For some reasons, some minor changes created new problems. For example, the new spring tensioner design couldn't work as it was twisting itself out of the slider and required some reinforcement.

I've made two extra pedals for friends to try and give me their feedback. The short board version you see is for PGB Artisan Cymbal, a cymbal smith in Montreal, Canada. Make sure to check out his stuff!

BOM

As there are now many configurations, I'll try to find an easy way to share the BOM. Currently, the way my model is done, it is quite some work. I'll start by listing the BOM for the longboard version with direct drive.

The only part that is special is the belt. I'm using a standard MXL timing belt assembled in reverse (teeth outside). You can buy the belt here through McMaster. The part-number is 1679K629.

Longboard - Direct

| Item | Quantity | Name | Material | Manufacturer | Reference Part Number |

|---|---|---|---|---|---|

| 1 | 1 | Dowel Pin 6 x 80 | Steel Class 10.9 | McMaster | 91595A490 |

| 2 | 6 | 05.0 x 13 x 04.0 - F 695 ZZ Flanged Ball Bearing | Steel 52100 | F695ZZ | |

| 3 | 3 | Shoulder Screw | Steel Class 10.9 | McMaster | 98451A122 |

| 4 | 11 | M4 Thread Insert | Yellow Brass | McMaster | 94459A170 |

| 5 | 1 | DP - Longboard | - None - | 3D Printed | |

| 6 | 1 | DP - Heel Shaft Base | - None - | 3D Printed | |

| 7 | 1 | DP - Board Base - Direct | - None - | 3D Printed | |

| 8 | 2 | DP - Frame Tube - Floor Longboard | - None - | Misumi | HFS3-1515-290 |

| 9 | 7 | Hex socket countersunk head screw M3x0.5 x 10 | Stainless Steel | ||

| 10 | 5 | Hex socket countersunk head screw M4x0.7 x 12 | Stainless Steel | ||

| 11 | 4 | Plain washer large grade A M3 | Stainless Steel | ||

| 12 | 6 | Hex socket head cap screw M3x0.50 x 10 | Steel Class 8.8 | ||

| 13 | 4 | Hex nut grade A & B M3x0.5 | Steel | ||

| 14 | 2 | 15.0 x 24 x 05.0 - 61802-2Z Ball Bearing | Steel 52100 | 61802-2Z | |

| 15 | 1 | "CONN JACK STEREO 1/4""" | - None - | Amphenol Audio | ACJS-MV-3 |

| 16 | 1 | 04.0 x 12 x 04.0 - 604 ZZ Ball Bearing | Steel 52100 | 604 ZZ | |

| 17 | 2 | 6.00 x 10.00 Sleeve Bearing | Bronze (8-14% Sn) | McMaster | 1677K221 |

| 18 | 1 | DP - Base | - None - | Laser cut | |

| 19 | 1 | DP - Bearing Mount | - None - | 3D Printed | |

| 20 | 1 | DP - Vertical Frame | - None - | Faztek | 20QE2020-5+7/8 |

| 21 | 1 | DP - Strengthener Width | - None - | 3D Printed | |

| 22 | 1 | DP - Feet - Strengthener Length | - None - | 3D Printed | |

| 23 | 1 | DP - Shaft Spacer Long | - None - | 3D Printed | |

| 24 | 4 | DP - Velcro | - None - | McMaster | 9736K63 |

| 25 | 1 | DP - Self-Kick Jack Frame | - None - | 3D Printed | |

| 26 | 1 | DP - Self-Kick Pad | - None - | 3D Printed | |

| 27 | 2 | DP - Stopper | - None - | 3D Printed | |

| 28 | 1 | DP - Self-Kick Absorber | - None - | 3D Printed - TPU 85A | |

| 29 | 1 | DP - Self-Kick Hit | - None - | 3D Printed - TPU 85A | |

| 30 | 12 | Prevailing torque nut M4x0.7 | Steel | ||

| 31 | 12 | Hex socket countersunk head screw M4x0.7 x 20 | Stainless Steel | ||

| 32 | 9 | Hex socket head cap screw M4x0.70 x 20 | Steel Class 8.8 | ||

| 33 | 3 | T-Slot Nut - M4 Drop-In | - None - | Faztek | 20 Series - M4 x 0.7 |

| 34 | 3 | Plain washer large grade A M4 | Stainless Steel | ||

| 35 | 2 | Hex socket countersunk head screw M6x1 x 20 | Stainless Steel | ||

| 36 | 2 | DP - Heel Pillow Block | - None - | 3D Printed | |

| 37 | 2 | DP - Beater Rotate | - None - | 3D Printed | |

| 38 | 1 | DP - Shaft - Beater Holder | - None - | 3D Printed | |

| 39 | 1 | DP - Beater | - None - | 3D Printed | |

| 40 | 1 | DP - Link Arm | - None - | 3D Printed | |

| 41 | 1 | DP - Beater - Shaft | Aluminum - 6061 | McMaster | 8974K22 |

| 42 | 1 | DP - Shaft Spring Knurl | - None - | 3D Printed | |

| 43 | 1 | DP - Shaft Spring | - None - | 3D Printed | |

| 44 | 1 | DP - Shaft Tube | Aluminum - 6063 | Amazon | A19082100ux1081 |

| 45 | 1 | DP - Spring Adjust Bearing | - None - | 3D Printed | |

| 46 | 1 | DP - Spring Adjust Slider | - None - | 3D Printed | |

| 47 | 1 | DP - Shaft Spacer Short | - None - | 3D Printed | |

| 48 | 1 | DP - Beater Weight | - None - | 3D Printed | |

| 49 | 1 | Socket Head Cap Screw M04 X 0.7 X 50 | Steel Class 10.9 | ||

| 50 | 1 | DP - Direct | - None - | 3D Printed |

Concept details

Short Board

The new short board version has 262 mm of usable length compared to the 309 mm from the longboards. I decided to keep the same base for both, so there are a few extra holes to accommodate for both versions. The only added part is the heel rest, other than that it's the exact same design, but shorter.

Belt drive

The belt drive is a replacement for the direct drive if you are looking for a different feel. Depending on the initial arm angle, the direct drive feel will always change as the lever length is changing. By using a belt, the current radius us constant, thus it offers a very constant and different feel.

As mentioned above, the "cam" can be changed quite easily. This will allow anyone to change the current design and fit their without anything else to modify other than the cam.

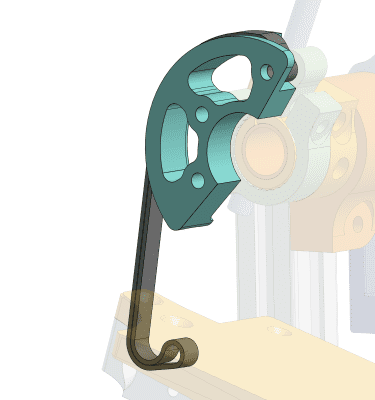

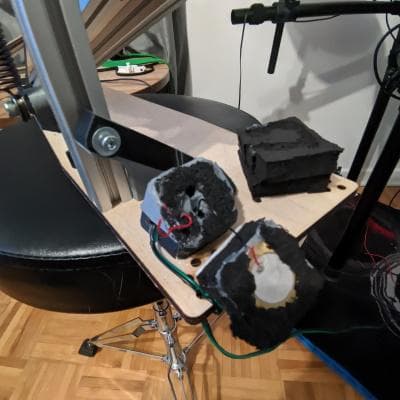

TPU absorbers

The self-kick used to be made from insulating foam. After some hits (a few months), I realized the foam was sheared and wouldn't absorb the hit like it used to be. This lead to a different feel, and more hit on the ground. I want the self-kick to be as silent as possible so back to the drawing board!

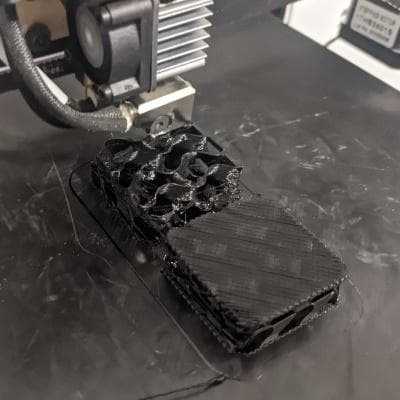

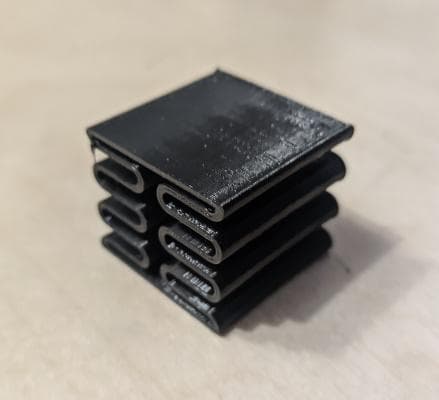

I wanted to see if some soft TPU (85A in hardness) could do something good with this pedal. I first tried to directly replace the square foam with a low infill 3D printed cube. Some tests were done with different infills, between 50% down to 10%. The infill pattern used is called "gyroid". As it turns out, the 50% infill were like solid blocks, they couldn't absorb any hit. The 13% and 10% were quite satisfying, the 13% being the one thinner and which the beater hits directly, shown below:

Even if I could squeeze these blocks very easily with my fingers, it seems like they won't absorb any of the hit from the bass drum beater. They stay solid upon a hit, I was very surprised. Back to the drawing board, again. I went online and looked for "3D printed spring" for some inspiration. I ended up looking with something like this:

The softness was good, as it bends very easily. The problem is that the block can move up top about 80% of its height, then it becomes a solid block, where every spring line is staked once over the other. As this absorber was quite easily compressed, this 20% deformation would be reached quite easily, the beater would reach this "blocky" state and still hit hard and make vibration. The goal is to keep it as silent as possible.

I decided to simplify the spring to the minimum, keeping a single loop, and ended up with something like this:

It turns out it is still too hard... The circle from the center made it too solid. But I knew I was onto something. The next step was simply to remove it, and print half a circle on the batter side, and I was ready to go!

I had to go heavy on the hot glue gun for this prototype as it didn't hold the first time. I wanted to focus on the sound reduction with this version, without modifying other parts. Next version, I'll be improving the assembly and look.

2020 vertical frame

I decided to change the Misumi 1515 aluminum extrusion for a Faztek 2020 for the vertical frame. This will make supply much easier, as the 2020 are very common. Faztek is a great Canadian supplier, but any equivalent will do. Please note that the end threads are currently M6 and different extrusion might need different threads. Make sure to adjust the holes and BOM if you can't use the M6 threads.

The aluminum extrusion now better match the bearing housing length, and fewer fasteners are required for assembly.

Detailed list of changes

| From Version | Part / Zone | Description | Done | Stage | Notes |

|---|---|---|---|---|---|

| V8 | squared Self kick | 2021-10-23 | Look will be improved considering the foam cutting limitations using scissors | ||

| V8 | Bigger extrusion for the vertical shaft | 2021-10-23 | Changed to FazTek 20x20 | ||

| V8 | Increase main bearing hole size to allow better alignment | 2021-10-24 | Add a gap. Top side is always -0.40mm smaller than bottom side. Added radial +0.05mm both side, +0.20mm on one side (0.25mm total) | ||

| V8 | Avoid tapping M3 into aluminum 15x15 extrusion when possible | 2021-10-25 | Long process, risky to break tap | ||

| V8 | Reverse link base printing direction and accommodate holes for board | 2021-10-25 | As a replacement for the ends threads on the 1515 extrusion | ||

| V8 | Thicken holes around inserts | 2021-10-25 | Some of the components cracked, increased by 1 to 2 mm depending on the cases | ||

| V8 | Bearing inner race bump for link arm | 2021-10-25 | |||

| V8 | Thicken spring arm M3 thread | 2021-10-25 | Slicer couldn't fill this part properly, weak point. Increased radius by 1mm | ||

| V8 | Prevent the spring arm from touching the main bearing housing | 2021-10-25 | Added a tapered flange | ||

| V8 | Reduce link thickness to prevent bearing squeezing | 2021-10-25 | Removed 0.10mm each side | ||

| V8 | Increased main shaft clearance | 2021-10-25 | From .02mm to .10mm | ||

| V8 | Belt/Cord drive | 2021-10-29 | |||

| V8 | Short board version | 2021-10-30 | |||

| V8 | Improve square self-kick look | 2021-10-31 | Will be OK for now. Need to evaluate a different jack type. | ||

| V8 | 3D Printed hoop stoppers | 2021-10-31 | |||

| V8 | Merge spring holder with feet strengthener | 2021-10-31 | |||

| V8 | Bring the spring closer to the frame and add a quick release | 2021-11-01 | Reinforce the quick release with the M3 screw | ||

| V8 | Reduce arm offset for small grooves | 2021-11-02 | Arm was slipping too easily on this version. Reduced from 0.20mm to 0.12mm | ||

| V8 | Cap the heel pillow block | 2021-11-13 | To prevent the shaft from falling | ||

| V8 | Reverse the flanged bushing direction | 2021-11-13 | It will be easier to cap the pillow block and keep the shaft fixed inside. | ||

| V8 | Fix the spring tensioner screw lifting itself up | 2021-11-21 | Will need to use an unthreaded insert for plastic: 91868A424 | ||

| V8 | Increase the pillow block strength | 2021-11-21 | Cracked after tightening. Added a note in part description for 3D printing with recommendations | ||

| V8 | Switch to F695 bearings and 5mm shoulder | 2021-11-21 | 4mm shoulder with M3 threads were a bit small. With this update, there is no need of M3 inserts any more | ||

| V8 | Fix mounting holes for vertical frame support | 2021-11-22 | |||

| V8 | Move the vertical frame further back and improve the front strengthener design | 2021-11-22 | |||

| V8 | Adjust the new screws and nut for the 2020 profile | 2021-12-04 | |||

| V8 | Longer beater nose | Cancelled | Was supposed to improve alignment. Not sure about the current look and strength, reverted back. | ||

| V8 | Use square nuts in the 1515 aluminum profile | Cancelled | Standard square nuts are too thin on McMaster (1.8mm) | ||

| V8.1 | Increase gap between heel block shaft and base | 2021-11-30 | Was reduced in previous version, now it's too close. Revert back to 1mm clearance (14.85mm on the CAD). Was 0.15mm | ||

| V8.1 | Add clearance for flat head on the base / heel block | 2021-11-30 | |||

| V8.1 | Clear the hex nuts sides when inserted from the sides | 2021-11-30 | Had to cut a small chamfer | ||

| V8.1 | Help preventing the Spring Adjust Slider from rotating | 2021-11-30 | Offset force rotates the part and the spring slides out. Moved the spring post inline and added extra twist support. | ||

| V8.1 | Revert back to the bushing inside the pillow block | 2021-11-30 | Impossible to align in the same part, | ||

| V8.1 | Add glue portholes in the heel block | 2021-11-30 | Screw aren't working for holding the shaft | ||

| V8.1 | Move the M4 Flat head in interference with the shaft away | 2021-11-30 | |||

| V8.2 | Reduce the part thickness for screw with t-slot nut | 2021-12-04 | They are currently 3mm out | ||

| V8.2 | Add a taper to the nut inserts | 2021-12-04 | |||

| V8.2 | Fix shoulder screw installation depth | 2021-12-04 | Need to space bearing and use blue thread locker | ||

| V8.2 | Add beater weight slider | 2021-12-04 | Maybe some people will need it. | ||

| V8.3 | Make the spring adjust stronger | 2021-12-11 | Fix the torsion in the part | ||

| V8.4 | Replace foam with 3D printed shock absorber | 2021-12-12 | Will enable fine tuning the response and feel | ||

| V8.4 | Improve 3D printed shock absorber | 2021-12-17 | Test different shapes. Use a slot instead of a hole to pass the wires through |

Conclusion

Again, I'm super happy with this version! The feel is great, and it's getting easier to build.

I'm still not a big fan of the 1515 extrusion as they are quite overkill as a board strengthener, but I don't have any equivalent in therms of strength and ease of use (no drilling, tapping, etc.). I'm still thinking about laser cut aluminum sheet, but I feel like it would make this project harder to build.

Also, I'm not currently satisfied with the bearing setup: there are quite a lot of F695ZZ for the purpose they have. I recently got the Iglidur I180 from IGUS, and I'll see if I can replace some bearing by 3D printed bushings.